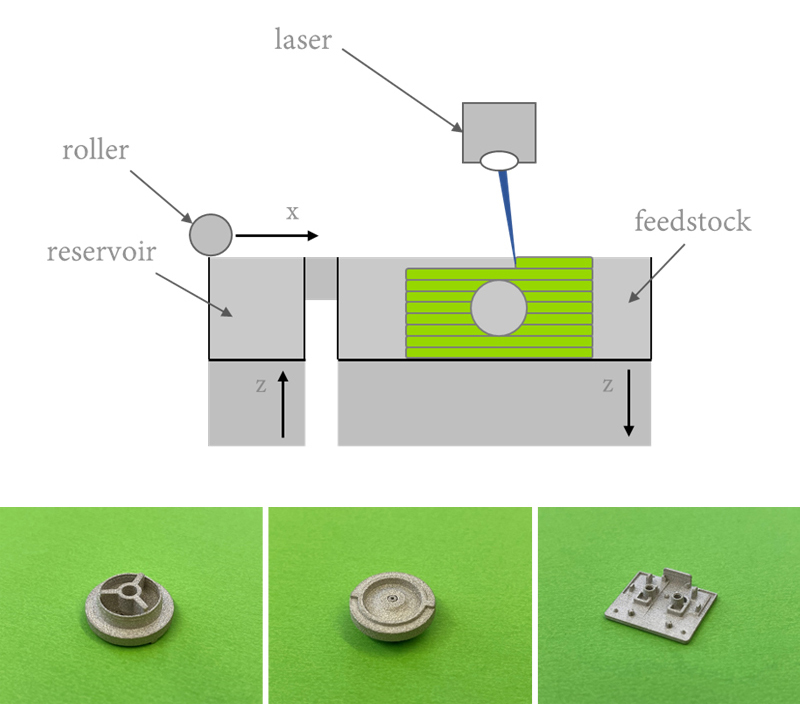

Cold Metal Fusion

This process runs on conventional SLS equipment for plastics printing. After a thin layer of the feedstock powder (metal powder + binder) has been applied in the build space, the binder is melted locally with the help of a laser. No support structures are necessary for the construction of the green body. The process is suitable for the production of prototypes as well as for series production of several thousand pieces.

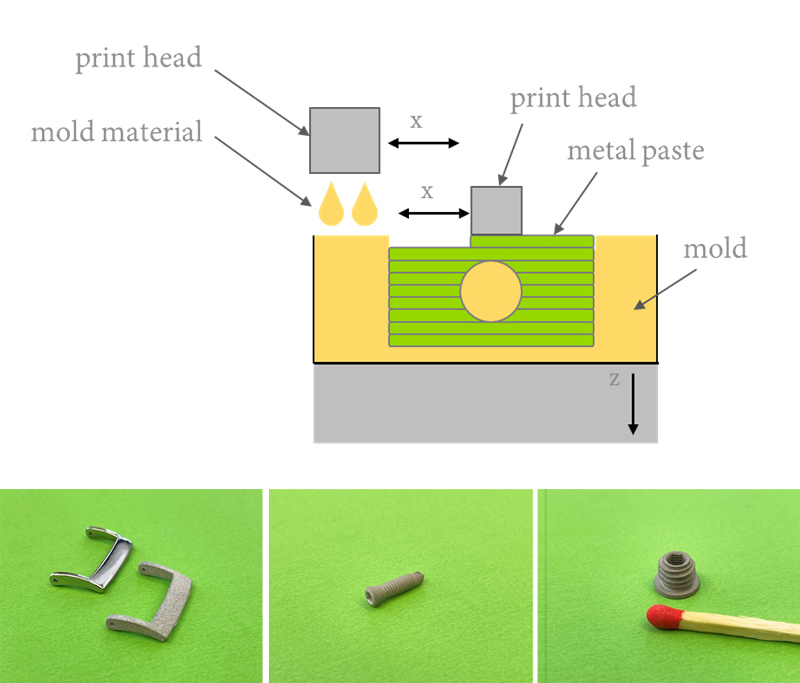

MoldJet

Here, a negative mould of the component is printed layer by layer. A metal paste is applied to the mould after each layer. The component is supported by the mould during printing so that no support structures are necessary. The MoldJet process enables series production of small to medium quantities up to approx. 100,000 pieces.