Tool and mold making

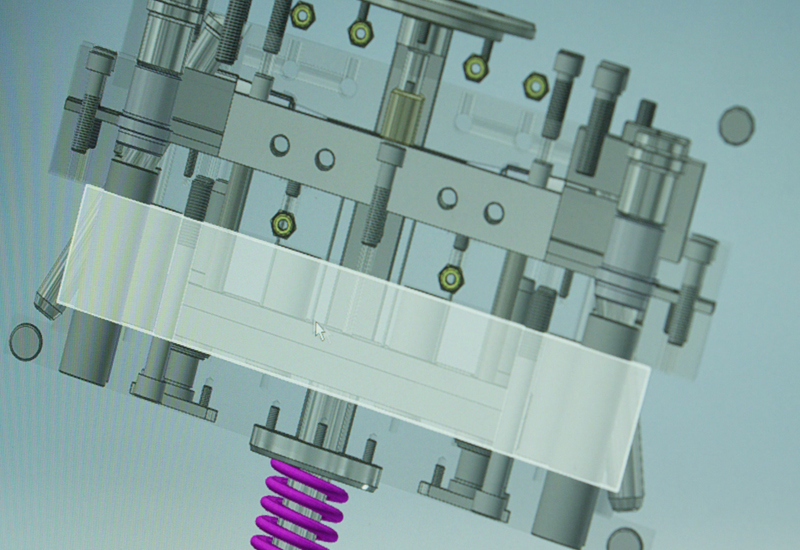

Tool and mold making

We have a fully equipped injection molding tool shop to implement your design ideas quickly and flexibly. Due to our in-house tool design and process simulation, we are able to adapt the tool optimally to your specifications.

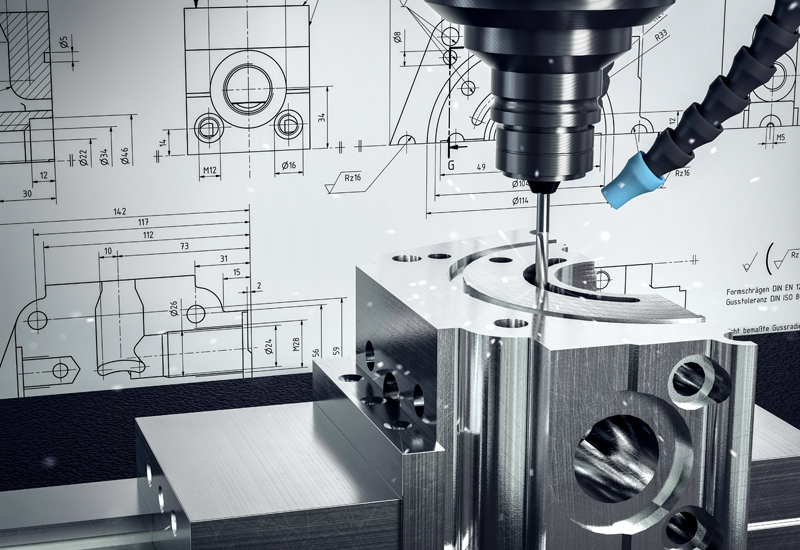

Mechanical engineering

Mechanical engineering

In our mechanical engineering department, we implement the tools and automation solutions tailored to your requirements in short terms and cost-effectively. The in-house design department, automation technology and electrical departments have many years of experience in the construction of semi-automated or automated special purpose machines, such as automated assembly machines.

Laboratory

Laboratory

We have a fully equipped metallographic laboratory for the analysis of microstructure, carbon content, density, hardness and more. In case of customer-specific requirements, it is possible to carry out series-related tests, such as microstructure tests without loss of time.

Feedstocks for special applications and special materials can be developed in-house and produced in small quantities.

Quality Control

Quality Control

Our quality management system is certified according to ISO 9001:2015 and IATF 16949. Quality assurance is comprehensively equipped with state-of-the-art measuring equipment. This enables us to measure geometric, surface-specific and metallurgical properties quickly, flexibly and reliably.