New materials for the respective processes

New materials for the respective processes

MIMplus Technologies develops the MIM and AM material precisely tailored to your needs. In our research and development department, our engineers develop raw materials for various alloys and composites, from hard metals (WC/Co, Stellite6,. . . ) to high-temperature materials (e.g. Inconel) and composites, which are not yet offered by commercial raw material producers. From laboratory batches of several kilograms to batch sizes for series production, we develop the materials for MIM and AM together with you.

Complex-shaped permanent magnets from recycled NdFeB

Complex-shaped permanent magnets from recycled NdFeB

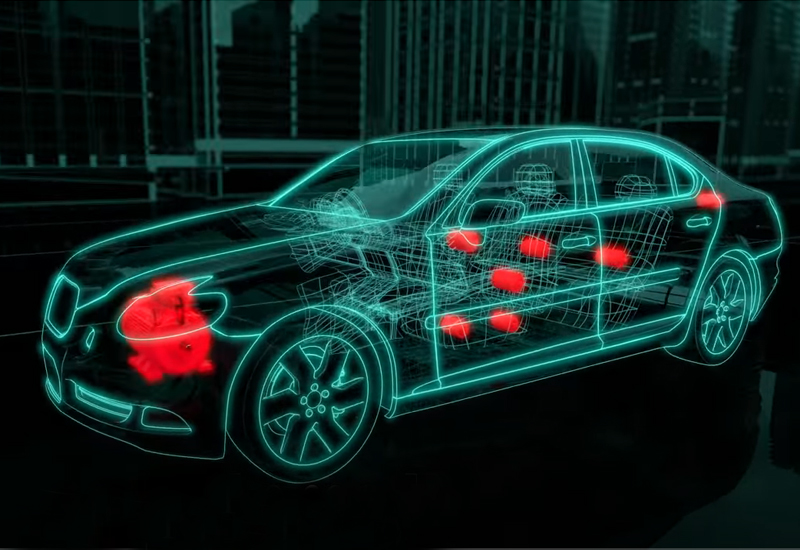

Our unique and innovative manufacturing process developed and patented by MIMplus Technologies allows us to manufacture highly complex molds for permanent magnets in the MIM process using the powder obtained from recycled NdFeB-magnets. The magnetic properties of magnets from our process are similar to that of sintered magnets from established processes but offer a much greater design freedom of the product.

Following the Proof of Concept (POC), together with our customers we are now developing this process ranging from recycling the magnetic material extracted from electronic scrap up to ready-made permanent magnets of complex shape.

Research projects with public funds

Research projects with public funds

MIMplus Technologies participates in research projects and is involved in several publicly funded projects in cooperation with leading partners from research and industry consortia. This provides access to the latest developments in materials, 3D-printing and production technology. Current and former projects are mainly in the field of 3D-printing (MAESTRO [Horizon2020]) or the development of the new materials (MIMLAS [AiF], REProMag [Horizon2020], MaXycle [Horizon2020]).

MIMplus Technologies was awarded the German Raw Material Efficiency Award 2017 with the Horizon2020 project REProMag in 2017.

MIMplus is currently pushing ahead with the industrialisation of magnet production from electronic scrap in the SUSMAGPRO project supported by the EU. The aim is to develop a circular economy in which the magnets are first identified, separated, reprocessed and finally processed into new magnets. MIMplus pursues the goal of producing recycled magnets using metal injection molding.

Co-operation with leading universities

Co-operation with leading universities

As a market leader, we are involved in a number of collaborations with leading universities as well as with the University of Applied Sciences in Pforzheim.