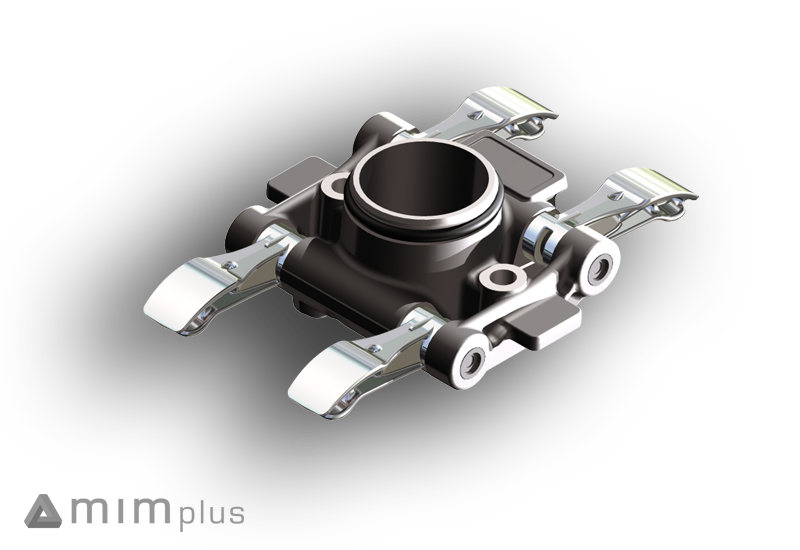

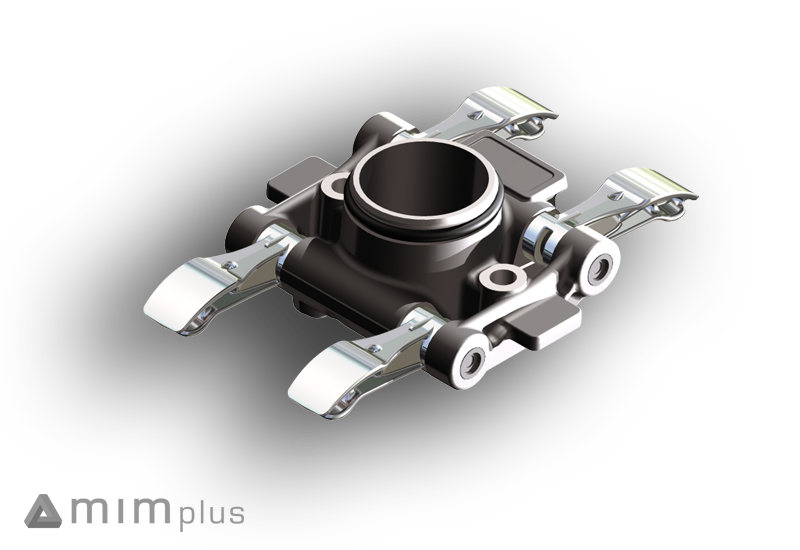

Valve-drive assembly

Valve-drive assembly

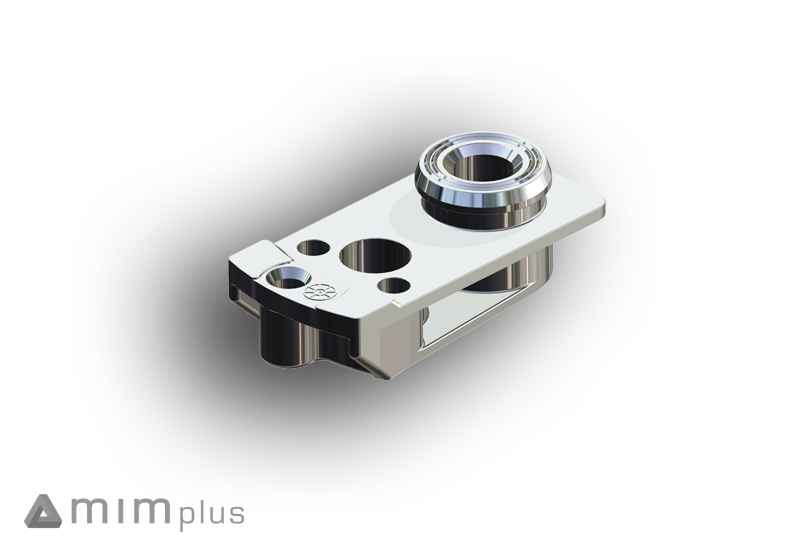

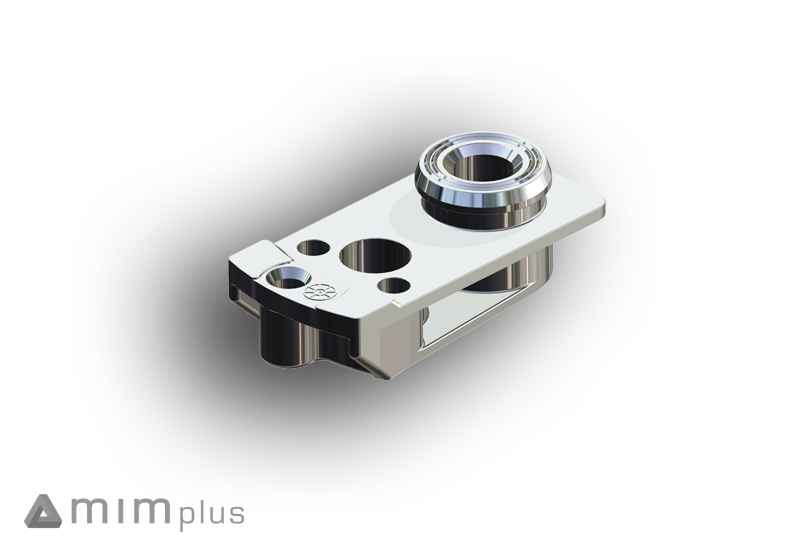

Connecting flange

Connecting flange

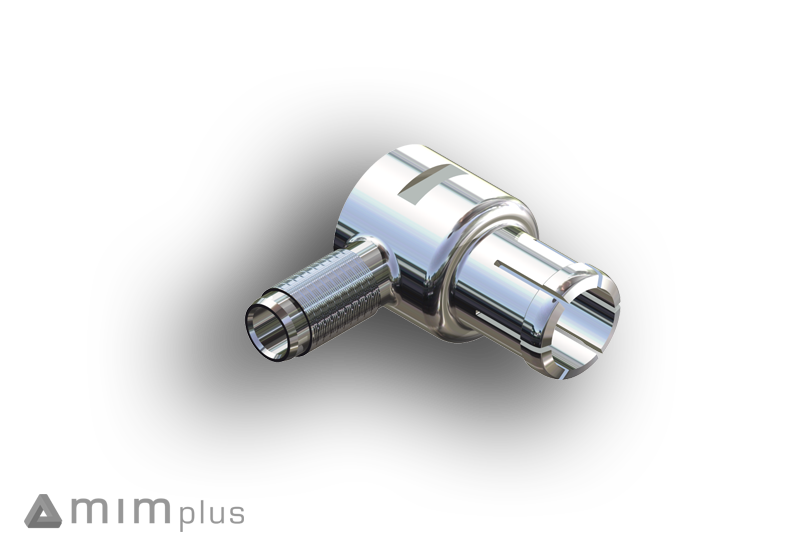

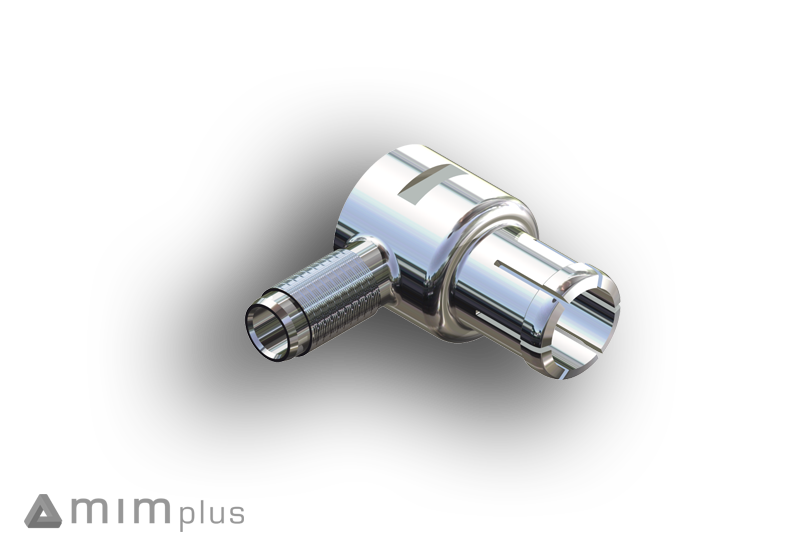

GPS angle connector

GPS angle connector

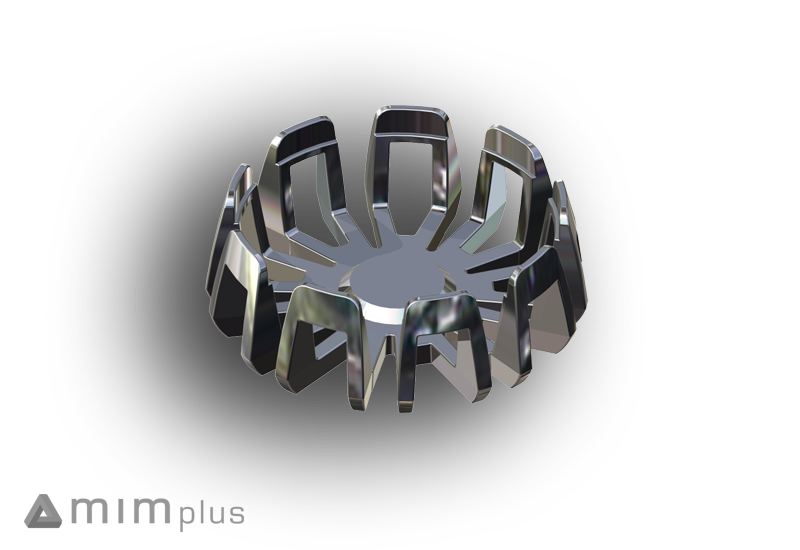

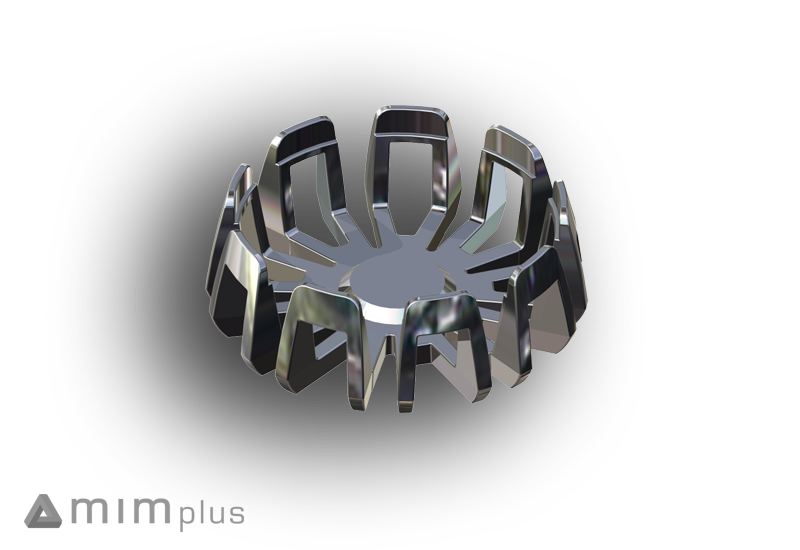

Complex titanium adjuster

Complex titanium adjuster

MIM as a production technology is particularly suitable for the automotive sector due to the high volumes involved. But AM also has a clear place here thanks to its many advantages. The fields of application for both technologies are particularly where, due to the high degree of design freedom, material can be saved and/or functions can be integrated. MIM enables lightweight construction like no other process. Another application is highly stressed components, as high-performance materials can be processed here that cannot be machined with other processes, or only with great effort. Parts for high-pressure fuel injection systems or components that are exposed to high temperatures, such as turbocharger blades, are also particularly suitable for our manufacturing technologies. Another field of application is cosmetic parts for the interior. Here, the freeform surfaces and decorative surfaces, which no other process can offer, can be realised, MIM and AM parts are also excellently suited as inserts for highly stressed plastic parts.

Valve-drive assembly

Valve-drive assembly Connecting flange

Connecting flange GPS angle connector

GPS angle connector Complex titanium adjuster

Complex titanium adjuster